PAD MOUNTED TRANSFORMER-ZGSL-2500-12.47-0.6

- Home

- Product

PAD MOUNTED TRANSFORMER-ZGSL-2500-12.47-0.6

The ZGSL-2500-12.47-0.6 is a high-capacity pad-mounted transformer designed for underground power distribution networks. It converts 12.47kV primary voltage to 0.6kV secondary voltage with 2500kVA capacity, making it ideal for industrial plants, commercial complexes, and utility substations.

Housed in a locked, weatherproof steel enclosure, this electrical transformer meets IEEE C57.12.28 standards for safety and reliability. Its compact design allows installation in space-constrained areas while delivering:

- ✔ 98.4% efficiency at full load

- ✔ Low-loss design (≤3.5kW no-load loss)

- ✔ Corrosion-resistant construction for harsh environments

Optional smart monitoring enables real-time performance tracking. Available for customization (ODM/OEM) to meet specific project requirements.

-

High Efficiency & Energy Savings

The ZGS-2500-12.47-0.6 pad mounted transformer delivers exceptional efficiency with optimized core design and high-grade silicon steel, achieving over 98% energy efficiency. This electrical transformer minimizes power losses, reducing operational costs for utilities and industrial applications. As a trusted transformer supplier, we ensure compliance with IEEE C57.12.34 standards for reliable performance. -

Durable & Weatherproof Construction

Built for harsh environments, this pad mounted transformer features a robust, corrosion-resistant tank and tamper-proof design. Its compact, low-profile structure saves space while maintaining superior thermal performance. Our transformer factory conducts rigorous testing, including impulse and temperature-rise tests, to guarantee long-term durability. -

Flexible Customization (ODM/OEM)

We specialize in custom pad mounted transformer solutions, offering adjustable voltage ratings (12.47kV to 0.6kV), multiple cooling options, and protective features. Whether you need standard or modified designs, our ODM/OEM transformer services provide tailored solutions for your specific project requirements. -

Competitive Pricing & Global Availability

Request our transformer price list today for cost-effective, high-quality solutions. As a leading transformer manufacturer, we combine advanced production capabilities with efficient logistics to serve customers worldwide. -

Trusted Expertise & Quality Assurance

With 20+ years in electrical transformer manufacturing, we maintain strict quality control and ISO-certified processes. Our pad mounted transformers undergo thorough testing to ensure safety, reliability, and peak performance in all operating conditions.

| Type | Pad mounted transformer |

|---|---|

| Model | ZGSL-2500/12.47-0.6 |

| Installation | Outdoor |

| Altitude | ≤1000m |

| Rated Power | 2500KVA |

| Cooling Method | ONAN |

| Primary Voltage | 12470/7200V |

| Secondary Voltage | 600/347V |

| Rated Frequency | 60HZ |

| Insulation oil | Mineral oil |

| Tapping Range | ±2×2.5% |

| Temperature rise (℃) | 65 |

| Connection Group | Ynyo |

| Impedance (%) | 5-48% |

| Total weight (kg) | 7020 |

Pad-mounted transformers are ground-level, enclosed electrical transformers commonly used in urban and suburban power distribution systems. Their key applications include:

-

Underground Power Distribution Networks

Widely deployed in areas with underground cables (e.g., residential neighborhoods, commercial districts) to step down medium voltage (e.g., 15–35 kV) to low voltage (120/240V or 480V) for end users. -

Commercial & Industrial Facilities

Provide localized power transformation for shopping malls, office buildings, factories, and data centers where aesthetics, safety, and space efficiency are priorities. -

Residential Subdivisions

Serve as distribution nodes in housing developments, ensuring safe and reliable power delivery while minimizing visual and noise impact. -

Renewable Energy Integration

Used in solar/wind farms to step up or down voltage before feeding into the grid or supplying nearby communities. -

Public Infrastructure

Support hospitals, schools, airports, and street lighting systems by integrating seamlessly into urban landscapes. -

Temporary Power Supply

Deployed for construction sites or emergency power restoration due to their modularity and quick installation.

1. Shipment, Handling, Rigging & Storage

- Inspect the transformer for shipping damage upon arrival. Report any issues to the carrier immediately.

- Use only designated lifting lugs and appropriate rigging equipment rated for the transformer’s weight. Never lift by bushings or radiators.

- Store the transformer upright on a level, dry surface. Protect from weather and flooding. For long-term storage, seal all openings and monitor silica gel breathers.

2. Transformer Installation

- Crane Lifting & Rigging: Attach slings to marked lifting points. Use spreader bars if needed to avoid tank deformation.

- Jack & Skid: For short moves, use jacks and skids under the base. Move slowly and avoid sudden movements.

- Foundation: Place transformer on a flat, solid, non-combustible pad with proper drainage. Anchor as required by local codes.

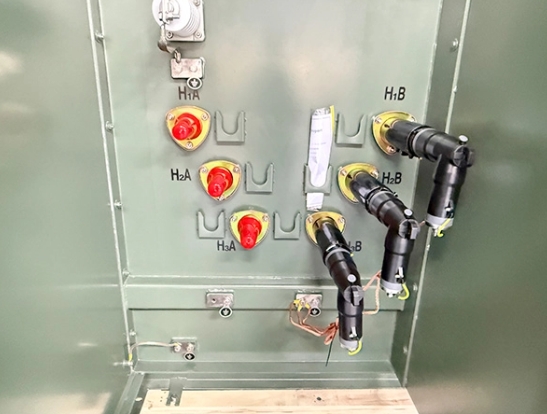

- Compartment: Ensure HV and LV compartments are accessible and free of debris. Check gasket seals for integrity.

- Grounding: Connect tank and neutral points to a reliable earth ground per IEEE/NEC standards.

- High Voltage & Low Voltage Connections: Clean and torque all cable terminations to manufacturer’s specifications. Use proper lugs and insulation.

- Dielectric Fluid: Check oil level and top up with approved fluid if necessary. Sample oil for moisture and dielectric strength if required.

- Transformer Pressure: Verify pressure relief device is operational. Check for correct internal pressure or vacuum as specified.

- Other Aspects: Install required signage and barriers. Confirm all accessories are installed and functional.

3. Pre-Energization

- Perform insulation resistance and turns ratio tests. Confirm all connections are tight and correct.

- Verify tap changer is set to the correct position.

- Check oil level, absence of leaks, and operation of gauges and alarms.

4. Post-Energization

- Monitor for abnormal noise, vibration, or temperature rise.

- Check for oil leaks and monitor gauges for pressure and temperature.

- Record initial load and voltage readings.

5. Switching Operation

- Operate switches only under no-load conditions unless rated for load-break.

- Follow lockout/tagout procedures before maintenance.

- Use insulated tools and wear appropriate PPE.

6. Protection

- Ensure fuses, surge arresters, and relays are installed and rated correctly.

- Test protection devices per manufacturer’s recommendations.

7. Accessories

- Check operation of temperature gauges, pressure relief devices, oil level indicators, and gas relays.

- Maintain and calibrate accessories as required.

8. Maintenance

- Perform periodic inspections for leaks, corrosion, and proper operation of all devices.

- Sample and test dielectric fluid annually or as recommended.

- Clean bushings and compartments regularly.

9. Field Acceptance Test Guidelines

- Conduct insulation resistance, turns ratio, and winding resistance tests before energization.

- Compare results with factory test reports and standards (e.g., IEEE C57.12).

- Document all test results for future reference.

10. Tables and Procedures

- Refer to the manufacturer’s manual for torque values, oil specifications, and test limits.

- Maintain a log of all inspections, tests, and maintenance activities.

- Follow standard operating procedures for all field operations.

RELATED PRODUCTS